project06:Frontpage

Factory of the Future

In this graduation project the Factory of the Future(FoF) is researched in the context of the present and near future. The goal is to formulate a design proposal for a factory building in Amsterdam. This plan is based on scenarios regarding the technological developments of the industry, new possibilities for distribution networks, and the relations between factories and urban and social fabrics.

Goals and research

Architectural research questions: - The logic of the factory in itself, regarding inputs, processes and outputs. - How technological developments could shape the factory of the future different than it is today. - How a factory can be shaped to fit into the context of a contemporary western urban area, regarding the economic, environmental and spatial aspects. - The possible connection and openness between life within a factory and human life outside of the factory. Material, parametric and robotic research: - The parametrics and calculations regarding double curved beam structures. - The use of curved wood components in architecture using generic and cheap materials such as beams and planks.

Automation in factories

The current trend in production is the transition from mass production towards a mass customized workflow (Oosterhuis, 2014). This means the use of ‘intelligent’ production methods to fabricate a variation of products at the speed and costs of mass production. “A mass customization system should possess a stable although still flexible and responsive set of processes, that are capable to deliver a finite number of customization options.” (Boër, Claudio, & Pedrazzoli, 2013) Factories try to transform a raw material into a demanded product at a cost-effective competitive way. In the case of automation in factories this cost-effective aspect is commonly achieved by the reduction of human labor. To sharpen the scope in this FoF the focus will be on products related to the building industry.

Reducing human labor in factories generally includes both automatic transportation within the factory as the automated production of goods and the link between these two aspects. Automated transportation within the factory regards intelligent order systems that are translated to distribution systems that control orders throughout all the steps in the production process. To transform a raw product into a final product, usually several steps need to be taken to do so, though per final product the steps may differ. The routing of such a differentiated factory outline is an opportunity for the FoF.

Automated production is the use of variable and intelligent production methods, such as the robotic arm or intelligent CNC or printing machines. The economic opportunities are rather in the field of the creation of series of comparable objects rather than the creation of truly unique object. This way the errors in the processes can be researched and prevented, granting full use of possible machine time. The integration of the two processes is a key factor. Both automated routing and production grant the minimum use of human labor, but also grant the opportunity to enter human aspects to the process if a certain step in the production process can be achieved more straight-forward and cheaper than automated. Both the automated routing throughout the steps of a production process and automated steps within this production process form the basics of the design of the FoF. These aspects are also supported by the Dutch government for further exploration in universities and industries (Team Smart Industry, 2014).

Relation of the factory to social aspects

The design of factories is largely determent by revenue. This is a combination of the costs of production (labor + machines), purchase of raw materials, transportation costs and sales of products. All the costs should be less than the price of a product. Over the last decades production flocked around spots with cheap labor in e.g. Asia, this effect was amplified by low costs of transportation. In a paradigm with automated factories, the influence of labor costs on the revenue decreases and increasing the share of transportation costs on the final product. This allows for and stimulates production closer to the end user and by that decreasing the need for transportation. Other aspects that could decrease the distance between factories and the end users are that factories are getting cleaner and circular in their planning and that production on demand may ask for a fast delivery to the client for the reason no stock can be made producing unique products.

In contemporary urban design a new way of coping with factories is needed. In the pre-offshoring era the factories were at the outskirts of the city, mainly due to pollution. In the near future factories, when not polluting, may need to be closer to the client.

A way of looking at this is by creating a network structure of factories rather than a building - as an object - focused approach. In this approach, inspired by the network structures of Constant Nieuwenhuys (Wigley, 1998), the automated production facilities have a space that is separated but intertwines with the human world. The human world is focused on the celebration of free-time due to the decline of labor. This forms a framework for the social context of the FoF.

Design to robotic production

The studio track focusses on ‘design to robotic production’. This means the use modern production techniques and the research of it on the architectural project. Research is carried out on the practical, how to fabricate and make certain building components, and on the larger scale, how this influences architecture. The focus of design studio is less on the automation of certain existing processes, but more on looking for new possible ways of production and looking for new ways to design with these. Certain possibilities in production technology lead to certain ways of architectural design and vice versa. The creation of large scale architecture doesn’t only rely on context, functional, architectural or designer driven arguments, but may also relate to the very tiny detail in the production process.

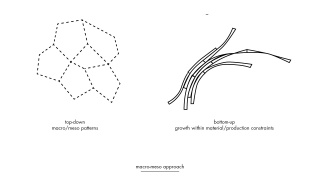

Throughout the architectural scales A framework of working towards an integrated design project is the use of the macro, meso and micro scale. The macro captures the architectural towards the urban scale; the meso scale is the architectural fragment or focusses on the building components, while the micro scale focusses on the production, the building product and it’s specific characteristics. The integration between the scales, the influence of one scale on the other, grants the possibility for an integrated architectural project.

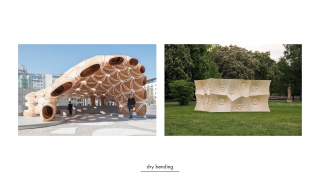

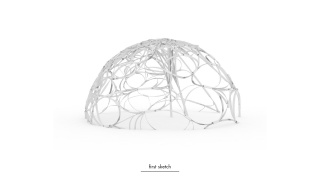

The macro approach of the FoF incorporates the use of swarm simulations to make both a functional and spatial layout on the level of the complete site. Internal parameters, based on the two main functions on the site, the factory and the recreation are taken into account. External parameters, such as lines of sight and global routing are taken into the model as well. This generates a rough geometry to work with in the project. The meso scale focusses mainly on the structural aspects of the building.The formal style is partly inspired by the work of Svilan (2017), though the underlying system is quite different. Force lines are used to generate curved beams running along the macro generated surfaces. The forces in a building are roughly separated in tension and compression forces.

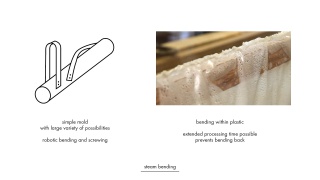

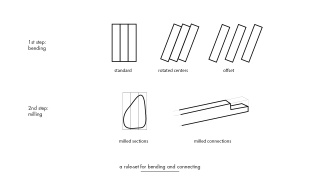

Wood beams are suited to cope with the compression forces, while steel rods can take the tensile forces. The beam structure are based on both an 3D outside layer of the building and the several 3D outlines of the inner spaces. The compression forces are used to generate the position of the wood beams, these follow the force lines and the macro shape. Tensile steel rods are added both on the surfaces between the beams as between the surfaces. This way the compression force elements are thoroughly connected, a space frame is established. The meso step limits the shapes generated by the macro geometry. It dictates the maximum curve in a certain piece, the maximum span of a beam and the layering of the macro geometry. The micro approach is based on research regarding ways to generate curved wood structures out of generic wood materials such as beams and planks. Production tests have beam carried out on both Styrofoam and wood. In the Dessau DIA robotic lab tests have been carried out on Styrofoam beams to test the bending ability by kerf-cutting perpendicular to the beams main direction. And in the Netherlands more tests have been carried out to see the effects of kerf-cutting on wood beam bending and the material possibilities. Traditional ways of fabricating curved wood beams include: steam bending and sheet lamination. Both of these methods require the use of time consuming and expensive molds. The use of kerf-cutting was a way to try to make the process more simple. The kerfs are distributed along a beam according to the desired curve; this grants for a variable curve along the profile length.

Reflection

Parametric design and robotic production should not be seen a substitute for human activity, but rather as an extension in possibilities. It grands new opportunities in design of architecture and building components. Parametric design in my graduation project is used in two distinct ways. At first the generation of certain layouts or rough geometry. These can be considered as certain underlying layers of information for the design, though it is up to the designer to transform these into architecture. It should not be considered an automated process, rather as an extension of the designers tools. The second way parametrics are used in my design process is by the generation of geometry that has a close relationship to the production process. It doesn’t mean there are no manual steps in this process, but here the relation between the design, the component and eventually the robotic toolpaths have a quite obvious link.

Bibliography

- Boër, S., Claudio, R., & Pedrazzoli, P. (2013). Mass Customizationand Sustainability: An Assessment Framework and Industrial Implementation. New York / London: Springer.

- Oosterhuis, K. (2014). Game Changers. Retrieved from Oosterhuis.nl

- Svilan, T. (2017). Grove Tab Submission. Tallinn architecture biennale, Folly Competition.

- Team Smart Industry. (2014). Actieagenda Smart Industry.

- Wigley, M. (1998). Constant's New Babylon : the hyper-architecture of desire.

Location

Kop van Java Eiland, Amsterdam

This part of Amsterdam is in the middel of the Ij, a large area of water. There hasn't been built since the transformation of the area into an area with shops, offices and housing. Before this transformation there these used to be the docks and industry of the city.

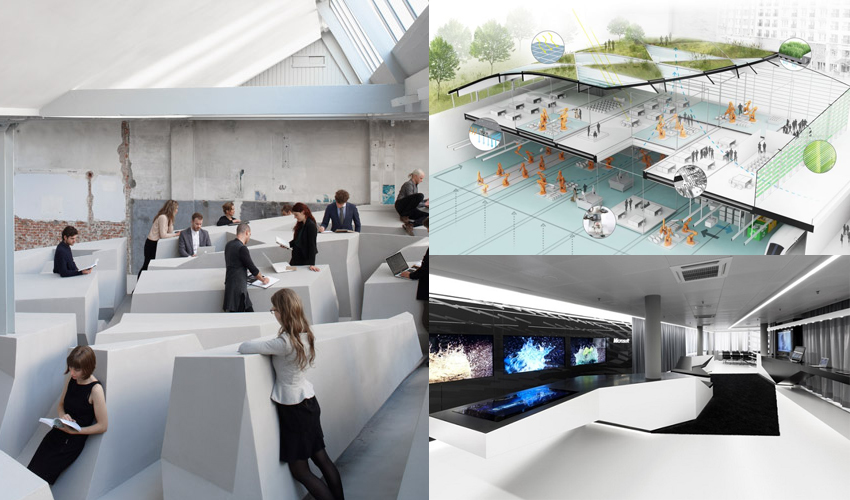

Referencese

Future office spaces by RAAF, HENN and Aztec.

Future office spaces by RAAF, HENN and Aztec.

New Babylon by Constant. Fluent artificial, by robots curated, world.

New Babylon by Constant. Fluent artificial, by robots curated, world.