project01:Frontpage

Benjamin Kemper

Running Out Of Gas On The Fast Lane

Repurpose of abandoned drilling rigs in the North Sea (in 20-50 years)

Humans are facing the dangerous consequences of the climate change. Especially the population of the Netherlands, which has to face rising sea levels. An undesired, nor not impossible scenario, would be the loss of livable land due to flooding. The loss of building and living area would result in drastic changes to the means of life. On the one hand, we need to research possibilities to slow down the process, and also change our way of life. However, on the other hand, we must look for concepts and design proposals to support a lifestyle with radical climate changes.

Our society, human behavior, and cities are changing due to the exponential progress of technology. How are we going to live in a future, and which role will architecture play in an augmented world? It might emerge as a balancing act between utopia and dystopia, between the total dependency and repression of the machines and the freedom to achieve more than we ever imagined. Society’s addiction to technical devices emphasizes the urgency at hand to begin to work with new technologies instead of denying the process categorically.

Status Quo: http://rbse.hyperbody.nl/index.php/project01:P2

Project Video

TU Delft TV Video

P5 Preparation

Soft Architecture Proposal

0. Status Quo

Wind Analysis

Inspiration

Prototype 1st Iteration

Prototype 2nd Iteration

I. Prototype Fragment

II. Silicone

Silicone Company

Wacker Silicones

Recipe (Components)

Modification of the recipe will cause:

- different curing times (hours to minutes)

- variation in pot life (hour to minutes)

- change in viscosity (fluent to stable)

III. Silicone Expertise

Traditional Silicone Casting

Bachelor thesis in cooperation with Luisa Roth @ Technical University of Cologne

Silicone Molds + Counter Plaster Forms:

Making Of:

Pneumatic Silicone

Swarmscape - MSc1 project in cooperation with Mindaugas Arlauskas, Olav van der Doorn, and Daniel Fischer @ hyperbody, TU Delft

Prototype:

Making Of:

IV. Architecture/Design References

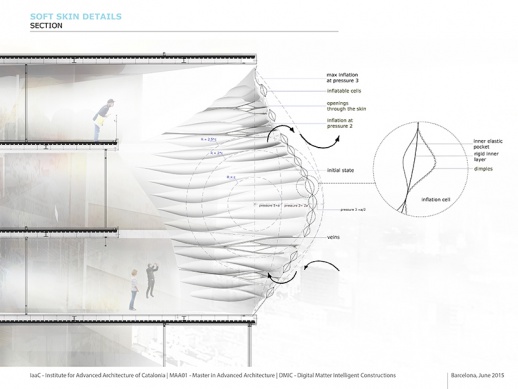

IAAC - Soft Skin

Inflated Silicone Skin + Façade Section:

Nameless Architecture - The Door

Silicone Door (Reinforced Epoxy Resin, Translucent Silicone Resin + Steel Wire):

Product Video:

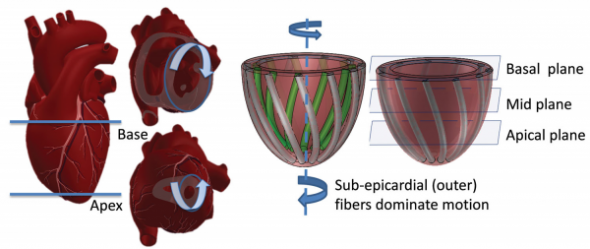

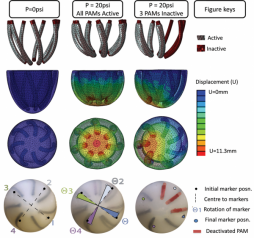

Harvard Bio Design Lab/Soft Robotics Toolkit - Cardiac Simulator

Artificial Silicone Heart + Muscles:

A Bioinspired Soft Active Material and Cardiac Simulator:

V. Responsive Skin

Proposal Living Architecture

Reference Living Architecture

Philip Beesley - Hylozoic Ground

Artificial Muscles

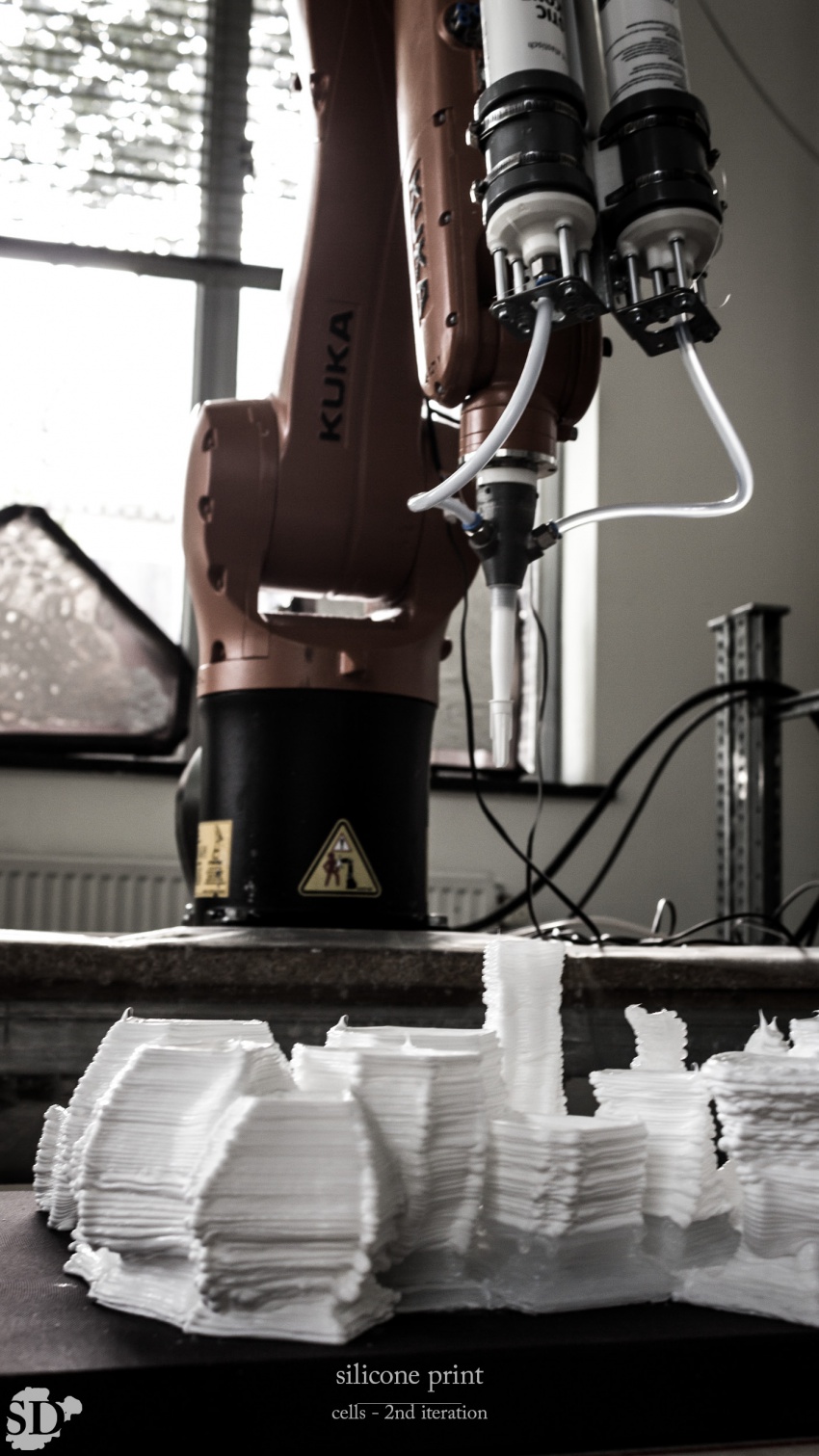

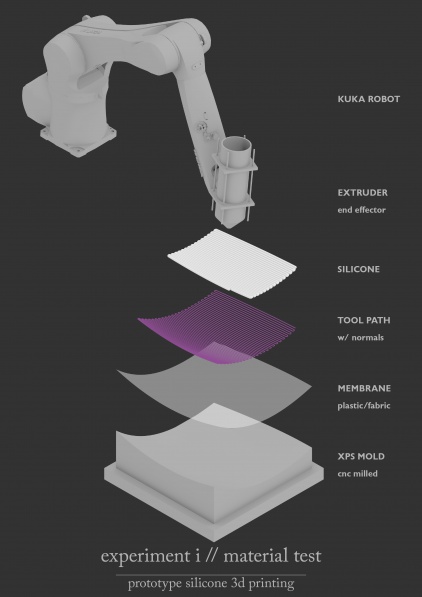

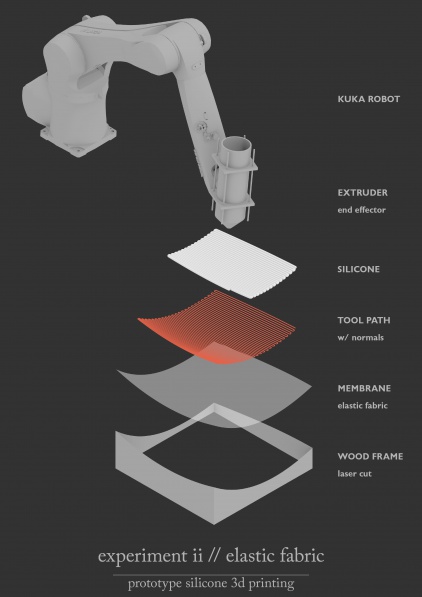

VI. Silicone 3D Printing

Reference

ACEO® 3D Printing

Proposal

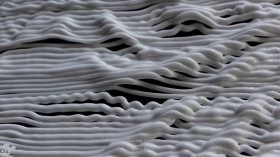

Large scale 3D printing of silicone on double curved surfaces

Basic steps 3D printing siliocne on double curved membrane (single layer // multi layers w/ different directions)

![]()

![]()

Advanced steps + modifications to a responsive skin (different silicone types // embedded plastic structure // embedded sub structures // embedded artificial muscles // combination)

![]()

![]()

![]()

![]()

![]()

Initial Experiments

3D print of silicone on double curved surface // 3D print of silicone on elastic double curved fabric

VII. Manual Experiments

VIII. 1st Robotic Experiment

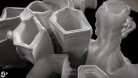

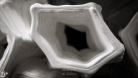

IX. 2nd Robotic Experiment

X. Combination Wood (TBC)

Inspiration

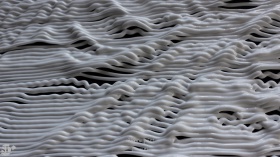

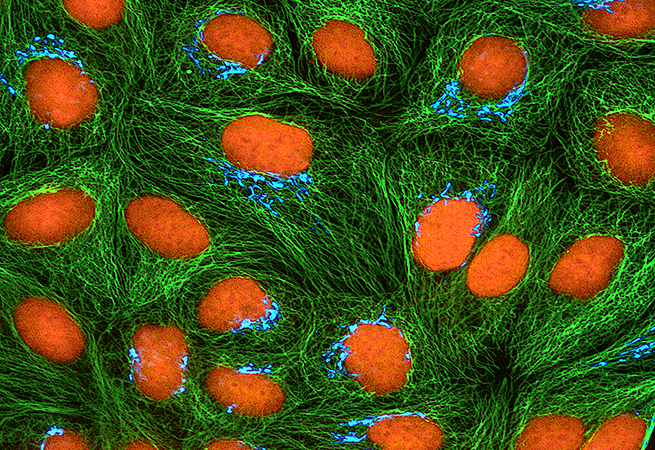

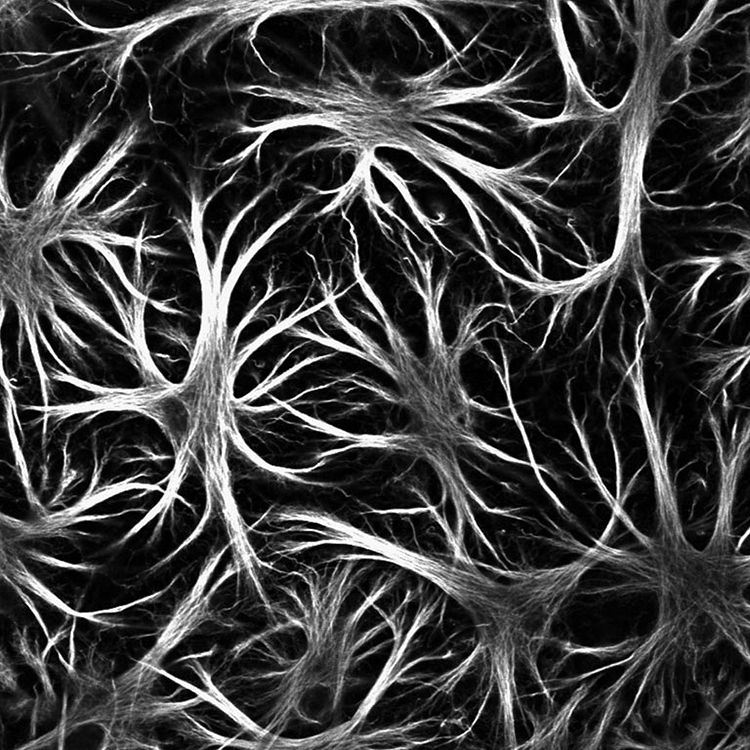

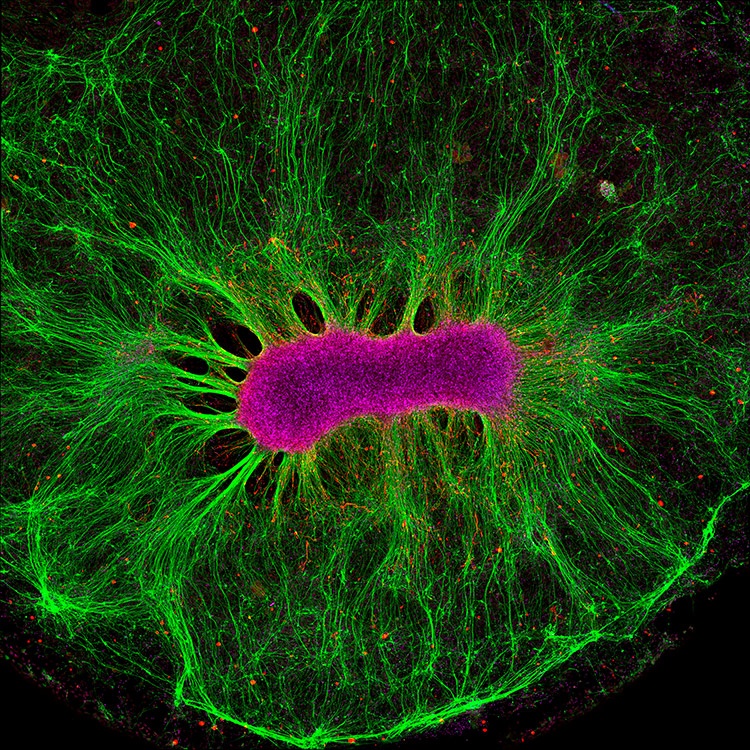

Microscopic exposures of cells and molecular biology @ Cell + Upworthy