Difference between revisions of "project02:P1"

| (85 intermediate revisions by 2 users not shown) | |||

| Line 1: | Line 1: | ||

__NOTOC__ __NOTITLE__ | __NOTOC__ __NOTITLE__ | ||

| + | [[File:Prototypes_banner.png| 850px]] | ||

| + | <div style="height:30px; width: 870px; margin:0px; padding: 0px; padding-top: 20px; border: 0px;"> | ||

| − | <div style="height:30px; width: | + | <div style="float:left; width: 109px; height 30px; font-color: #ffffff; border: 1px solid #000000; background-color: #ffffff; margin-right:10px;" align="center">[[project02:Frontpage|'''Concept''']]</div> |

| + | |||

| + | <div style="float:left; width: 109px; height 30px; font-color: #ffffff; border: 2px solid #000000; background-color: #ffffff; margin-right:10px;" align="center">[[project02:P1|'''Prototypes''']]</div> | ||

| + | |||

| + | <div style="float:left; width: 109px; height 30px; font-color: #ffffff; border: 1px solid #000000; background-color: #ffffff; margin-right:10px;" align="center">[[project02:P2|'''P2 ''']]</div> | ||

| + | |||

| + | <div style="float:left; width: 109px; height 30px; font-color: #ffffff; border: 1px solid #000000; background-color: #ffffff; margin-right:10px;" align="center">[[project02:P3|'''P3 ''']]</div> | ||

| + | |||

| + | <div style="float:left; width: 109px; height 30px; font-color: #ffffff; border: 1px solid #000000; background-color: #ffffff; margin-right:10px;" align="center">[[project02:P4|'''P4 ''']]</div> | ||

| + | |||

| + | <div style="float:left; width: 109px; height 30px; font-color: #ffffff; border: 1px solid #000000; background-color: #ffffff; margin-right:10px;" align="center">[[project02:diverse|'''Media Studies ''']]</div> | ||

| + | |||

| + | <div style="float:left; width: 109px; height 30px; font-color: #ffffff; border: 1px solid #000000; background-color: #ffffff; margin-right:10px;" align="center">[[project02:comments|'''Comments''']]</div> | ||

</div> | </div> | ||

| − | + | <br> | |

| + | == Cross Laminated Timber (CLT) == | ||

| − | + | Timber is one of the most both sustainable and old construction materials. By laminating different layers of wood together, one can produce a structure with incredible strength. Main reason for this is the multidirectionality in fiber direction, that allows to work better with external forces. | |

| − | + | [[File:prototypes_clt.png| 850px]] | |

| − | < | + | <br> |

| − | + | == state of the art == | |

| − | + | ||

| − | + | Most of the CLT production is traditionally flat slates. The project 'The smile', which was constructed within the 2016 London design festival, can be sonsidered as state of the art in CLT construction. This pavilion is the worlds first single curved structural CLT building. | |

| − | + | see: http://www.thetulipwoodsmile.info/ | |

| − | + | ||

| − | + | [[File:prototype_thesmile.png|850px]] | |

| − | + | <gallery style="text-align:left" mode="packed-hover" heights="120px" > | |

| + | File:thesmile_p_01.jpg | ||

| + | File:thesmile_p_02.jpg | ||

| + | File:thesmile_p_03.jpg | ||

| + | File:thesmile_01.jpg | ||

| + | File:thesmile_02.jpg | ||

| + | File:thesmile_03.jpg | ||

| + | File:thesmile_04.jpg | ||

| + | File:thesmile_a_01.jpg | ||

| + | </gallery> | ||

| − | + | <br> | |

| − | < | + | |

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | == The goal - 3D (freeform) CLT == | |

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | [[File: | + | [[File:Prototype_01.gif| 850px]] |

| − | + | ||

| + | <br> | ||

| − | </ | + | == Prototype 01 - Pressing== |

| + | |||

| + | '''Is it possible to fabricate (and computationally calculate) a double curved CLT panel out of individual flat timber planks?''' | ||

| + | <p>The lamination of wood is a common process in timber fabrication. In 2016, the first single curved CLT pavillion was built in London, but there is no real architectural result of double curved CLT. The goal is to proof that the production of double curved CLT panels is possible overall. The experiment uses two molds that press prefabricated timber strips into a three dimensional shape. Wood glue is used to connect the strips permanently. Next prototypes will make use of the same mold and test the effects of different aspects, such as engraving curvature based patterns into the strips or variations in thickness. | ||

| + | |||

| + | <gallery style="text-align:left" mode="packed-hover" heights="120px" > | ||

| + | File:p01_01.jpg | ||

| + | File:p01_02.jpg | ||

| + | File:p01_03_wide.jpg | ||

| + | File:p01_04_wide.jpg | ||

| + | File:p01_05.jpg | ||

| + | File:p01_06_wide.jpg | ||

| + | File:p01_07_wide.jpg | ||

| + | File:p01_08_wide.jpg | ||

| + | File:p01_09_wide.jpg | ||

| + | File:p01_flexmold.jpg | ||

| + | </gallery> | ||

| + | |||

| + | |||

| + | <br> | ||

| + | |||

| + | == Prototype 02 - Bending== | ||

| + | |||

| + | '''Is it possible to avoid intense efforts of (traditional) form works to produce double curved laminated timber structures by making use of industrial robots?''' | ||

| + | The initial idea is to make use of industrial robots to bend several timber planks at onece into shape. A double curved surface will be the initial geometry for this experiment. Structurally relevant force lines on this surface will be the base curve lines for the bending. Required for these tests are an industrial robot, an endeffector ehich can grab several planks and a station in front of the robot to fix the planks in all three dimensions. With results from computational simulations, the Toolpath for the bending process will be generated. The moment the several planks are bent in position, they will be bolted or screw together to keep their geometry. The connection between the planks itself is another whole part of the experiment. Besides simple bolting, other options might be discovered. Furthermore it would be interesting to explore the effect ofpretreating the wood with patterns to influence the final geometry. | ||

| + | |||

| + | <html> | ||

| + | <iframe src="https://player.vimeo.com/video/99162538" width="850" height="350" frameborder="0" webkitallowfullscreen mozallowfullscreen allowfullscreen></iframe> | ||

| + | </html> | ||

| + | |||

| + | <gallery style="text-align:left" mode="packed-hover" heights="120px" > | ||

| + | File:p02_01.jpg | ||

| + | File:p02_02.jpg | ||

| + | File:p02_03.jpg | ||

| + | File:p02_04.jpg | ||

| + | |||

| + | </gallery> | ||

| + | |||

| + | |||

| + | <br> | ||

| + | |||

| + | == Next steps == | ||

| + | |||

| + | |||

| + | <html> | ||

| + | <iframe width="850" height="350" src="https://www.youtube.com/embed/-6Vu1GyYSbk?modestbranding=1&autohide=1&showinfo=0" frameborder="0" allowfullscreen></iframe> | ||

| + | </html> | ||

| + | |||

| + | <gallery style="text-align:left" mode="packed-hover" heights="120px" > | ||

| + | File:prototype_pattern.jpg | ||

| + | File:prototype_pattern_02.jpg | ||

| + | File:prototype_interlock.jpg | ||

| + | File:pavilion_innochain.jpg | ||

| + | File:thesmile_p_03.jpg | ||

| + | File:bench_proto.jpg | ||

| + | |||

| + | </gallery> | ||

Latest revision as of 08:59, 27 March 2017

Cross Laminated Timber (CLT)

Timber is one of the most both sustainable and old construction materials. By laminating different layers of wood together, one can produce a structure with incredible strength. Main reason for this is the multidirectionality in fiber direction, that allows to work better with external forces.

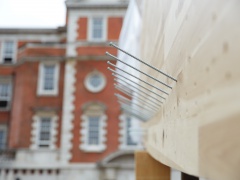

state of the art

Most of the CLT production is traditionally flat slates. The project 'The smile', which was constructed within the 2016 London design festival, can be sonsidered as state of the art in CLT construction. This pavilion is the worlds first single curved structural CLT building.

see: http://www.thetulipwoodsmile.info/

The goal - 3D (freeform) CLT

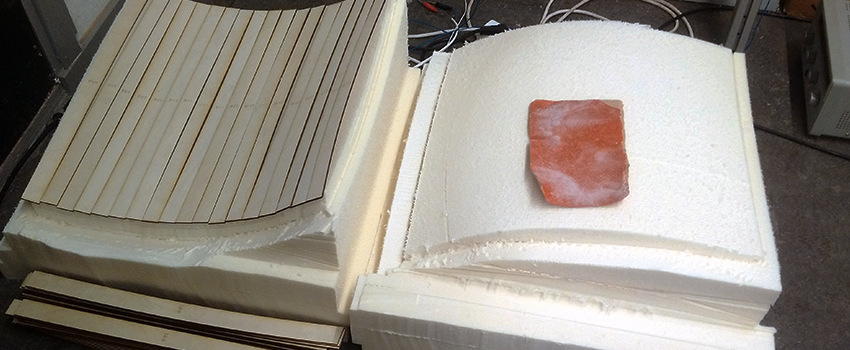

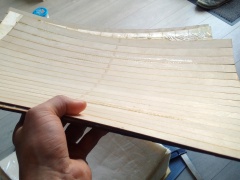

Prototype 01 - Pressing

Is it possible to fabricate (and computationally calculate) a double curved CLT panel out of individual flat timber planks?

The lamination of wood is a common process in timber fabrication. In 2016, the first single curved CLT pavillion was built in London, but there is no real architectural result of double curved CLT. The goal is to proof that the production of double curved CLT panels is possible overall. The experiment uses two molds that press prefabricated timber strips into a three dimensional shape. Wood glue is used to connect the strips permanently. Next prototypes will make use of the same mold and test the effects of different aspects, such as engraving curvature based patterns into the strips or variations in thickness.

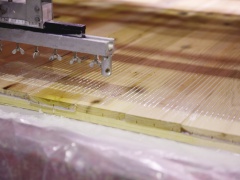

Prototype 02 - Bending

Is it possible to avoid intense efforts of (traditional) form works to produce double curved laminated timber structures by making use of industrial robots? The initial idea is to make use of industrial robots to bend several timber planks at onece into shape. A double curved surface will be the initial geometry for this experiment. Structurally relevant force lines on this surface will be the base curve lines for the bending. Required for these tests are an industrial robot, an endeffector ehich can grab several planks and a station in front of the robot to fix the planks in all three dimensions. With results from computational simulations, the Toolpath for the bending process will be generated. The moment the several planks are bent in position, they will be bolted or screw together to keep their geometry. The connection between the planks itself is another whole part of the experiment. Besides simple bolting, other options might be discovered. Furthermore it would be interesting to explore the effect ofpretreating the wood with patterns to influence the final geometry.

Next steps